Mazak have a large range of machine tools designed to handle all types of tasks. The full range can be viewed by visiting the official Mazak website. Below are a few of our favourites. Just click the image to view technical details.

Yamazaki Mazak Production Facilities |

Integrex i-150

The INTEGREX i-150 defines a new standard for small multi-tasking machines.

Production with higher efficiency and unsurpassed ease of operation thanks to a variety of Intelligent Functions.

Compact Machine Realizing DONE IN ONE Operation.

The INTEGREX i-150 will significantly improve your productivity of small workpiece machining.

Production with higher efficiency and unsurpassed ease of operation thanks to a variety of Intelligent Functions.

Compact Machine Realizing DONE IN ONE Operation.

The INTEGREX i-150 will significantly improve your productivity of small workpiece machining.

Integrex i series The INTEGREX i series, the fifth generation Mazak multi-tasking machine, features a large machining area and high accuracy plus ease of operation and convenient maintenance thanks to the ergonomic machine design.

• Long strokes for large workpiece capacity

• 5-axis simultaneous machining for complex workpieces

• Processing from raw material to finish workpiece in a single setup

• High-power spindle for heavy-duty cutting

• 5-axis simultaneous machining for complex workpieces

• Processing from raw material to finish workpiece in a single setup

• High-power spindle for heavy-duty cutting

Click here to view technical specifications

Integrex i-200s

The INTEGREX i-200S is the latest generation multi-tasking machine providing versatility and performance in a state of the art designed package, that is both environmentally friendly and energy efficient.

The INTEGREX i series, the fifth generation Mazak multi-tasking machine, features a large machining area and high accuracy plus ease of operation and convenient maintenance thanks to the ergonomic machine design.

• Long strokes for large workpiece capacity

• 5-axis simultaneous machining for complex workpieces

• Processing from raw material to finish workpiece in a single setup

• High-power spindle for heavy-duty cutting

• 5-axis simultaneous machining for complex workpieces

• Processing from raw material to finish workpiece in a single setup

• High-power spindle for heavy-duty cutting

Click here to view technical specifications and videos of the machine in operation

QTN 250 MSY II

The main spindle chuck size is 10-inch.

Options available include milling tools (M), Y-axis (Y) and a second spindle (S) to meet your needs.

Options available include milling tools (M), Y-axis (Y) and a second spindle (S) to meet your needs.

New generation world-class CNC turning centers that combine Advanced Technology, Productivity, and Value.

A wide variety of machine specifications - from 2-axis models to turning centers with rotary tool spindle and second spindle – is available to meet your production requirements.

A wide variety of machine specifications - from 2-axis models to turning centers with rotary tool spindle and second spindle – is available to meet your production requirements.

• Powerful main turning spindles with integral motors

• Full C-axis contouring available on machines with rotary tool milling spindles

• CNC programmable tailstocks

• Through-hole chuck packages

• Fast indexing turrets for maximum efficiency

• Automatic tool eye

• Easy integration of bar feeders and robotic loading for unmanned operation

• Full C-axis contouring available on machines with rotary tool milling spindles

• CNC programmable tailstocks

• Through-hole chuck packages

• Fast indexing turrets for maximum efficiency

• Automatic tool eye

• Easy integration of bar feeders and robotic loading for unmanned operation

Click here to view specifications and videos of the machine in operation

Slant Turn Nexus 550M

High rigidity construction for heavy duty cutting. Max. Swing/ Max. Machining diameter: Ø1040mm/ Ø 910mm. Max. Machining length: 2009mm/3144 mm (2000U/3000U). High speed milling.

The SLANT TURN NEXUS Series has the rigidity required for heavy-duty cutting of large work pieces. In order to meet a wide range of production requirements, a variety of center distances as well as different spindle bore sizes are available

• Designed to efficiently machine long shaft workpiece by powerful 45 kW (60 HP) (30 min. rating) spindle motor with maximum torque of 7000 Nm ( 713.8 kgf.m)

• Available with an optional NC steady rest with a maximum gripping range of Ø 410mm.

• Provides ease of operation thanks to the MAZATROL Nexus 2 CNC which also controls the tailstock and optional NC steady reast

• Available with an optional NC steady rest with a maximum gripping range of Ø 410mm.

• Provides ease of operation thanks to the MAZATROL Nexus 2 CNC which also controls the tailstock and optional NC steady reast

Click here to view specifications and videos of the machine in operation

INTEGREX e-500H-S

This machine makes it possible to meet any kind of production requirements thanks to the Y- axis stroke of 500 mm and maximum machining length of over 3000 mm (3m bed model).

Available with the option of a second spindle (S).

Available with the option of a second spindle (S).

Done-in-one processing for the machining of large workpieces.

Large swing and Y-axis stroke for large workpieces Roller guides on all linear axes for increased rigidity

Wide variety of optional equipment to reduce machining processes and improve machining capability

Large swing and Y-axis stroke for large workpieces Roller guides on all linear axes for increased rigidity

Wide variety of optional equipment to reduce machining processes and improve machining capability

• DONE-IN-ONE processing for the machining of large workpiece

• Long boring bar, rigid tool holder system with four clamping units for enhanced machining capacity.

• Large Y-axis stroke and powerful milling spindle improve machining capability and high accuracy machining.

• Y-Axis, off-center machining

• 240-degree B-Axis milling spindle positioning

• Single-setup machining • Second turning spindles

• Lower turret rotary tool spindles

• Large capacity tool magazine

• Long boring bar, rigid tool holder system with four clamping units for enhanced machining capacity.

• Large Y-axis stroke and powerful milling spindle improve machining capability and high accuracy machining.

• Y-Axis, off-center machining

• 240-degree B-Axis milling spindle positioning

• Single-setup machining • Second turning spindles

• Lower turret rotary tool spindles

• Large capacity tool magazine

Vertical CENTER SMART 530c

The Smart series are designed for high productivity, compact design and environmental considerations. They provide high efficiency machining thanks to the No. 40 taper spindle with maximum spindle speed of 12000 rpm and high speed feedrates.

The VERTICAL CENTER SMART Series is a world-class line of Vertical Machining Centers that combine advanced technology, productivity and value for a wide variety of machining applications. Grease-packed ceramic spindle bearings increase machine rigidity, reduce heat and help to reduce maintenance. The series offers Mazak's entry-level SMART control, with a user-friendly interface that provides the most current technology needed to quickly and accurately produce work pieces in Mazatrol Conversational or EIA formats.

• Compact footprint to maximize floor space • Robust 40-taper grease-packed spindles with ceramic bearings metal • SMART CNC control simplifies machine set up and increases operator efficiency • Performance enhancing Intelligent Machine features • Ergonomic control swings for easy operator viewing • High accuracy and productivity for a variety of industry applications • Easy integration of articulated robot for process automation

Click here to view specifications and videos of the machine in operation

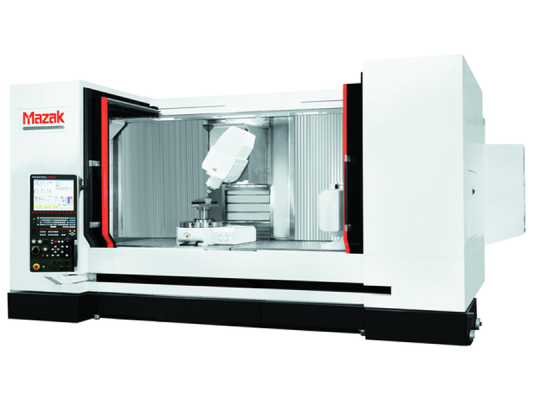

Variaxis i-600

Multiple-surface / Simultaneous 5-axis machining center. VARIAXIS i series Multiplex Surface / Simultaneous 5-axis machining center. The latest generation MAZAK 5-axis machining center designed for multi-surface machining delivering reduced in-process time, high accuracy and unrivalled machine ergonomics. Unsurpassed high-speed, high-accuracy performance. Max spindle speed 12,000 rpm (Option: 18,000 rpm, 30,000 rpm) Largest machining envelope: table size Ø500mm (i-500), Ø600mm (i-600), Ø700 mm (i-700), Ø800mm (i-800). VARIAXIS i-600 now available with SIEMENS SINUMERIK 840D sl CNC

5-axis simultaneous machining centers designed for exceptional versatility, now available with turning capability. The VARIAXIS i series features high-speed, high-accuracy performance. Largest machining envelope for this class machining center. Additionally, turning capability, 2 pallet changer systems and FMS are available to meet a large variety of production requirements.

• Done-In-One capability streamlines production and improves overall management • Intelligent Functions provide ease of operation and optimum efficiency • Wide range of spindle speeds available for exceptional versatility • Reliable cam-driven tool changer offers higher productivity • Various tool magazine capacities provide part-processing flexibility • High-rigidity table with roller gear cams eliminate backlash to ensure accuracy • MATRIX 2 CNC control provides unbeatable accuracy and increased productivity

Cybertech 5500T

Powerful, Heavy-duty CNC Turning Centers This powerful turning centre is equipped with a rotary tool spindle, lower turret and many new features to deliver higher productivity. A wide variety of optional specifications are available, including an automatic long boring bar stocker and advanced threading software that re-cuts threads, making CyberTech Turn especially suitable for oil industry components and other industries that machine long, large diameter workpieces.

• 12-position upper turret with turning and/or rotary tool abilities • Various bed lengths for long shaft applications • Deep hole boring with automatic changer • Fully Programmable servo tailstock • Mazatrol matrix 2 and matrix nexus 2 conversational programming • Powerful, Heavy-duty CNC Turning Centers • This powerful turning center is equipped with a rotary tool spindle, lower turret and many new features to deliver higher productivity. • A wide variety of optional specifications are available, including an automatic long boring bar stocker and advanced threading software that re-cuts threads, making CyberTech Turn especially suitable for oil industry components and other industries that machine long, large diameter workpieces.

VTC 800/20SR

VTC-800/20SR has been designed to meet the needs for today's challenging and diverse range of manufacturing applications where performance, flexibility and precision are key product attributes. The VT- 800/20SR offers excellent machining capacity for a large variety of work pieces.

Mazak’s Vertical Travelling Column (VTC) range of machining centres has been designed to meet the needs for today’s challenging and diverse range of manufacturing applications where performance, flexibility and precision are key product attributes. The flexible configuration of the VTC provides the capability to process an extensive range of components from medium to large across industries including aerospace, power generation, industrial equipment and general subcontract. The VTC range of products is available in either 3, 4, 5 and 6 axis configurations, which in conjunction with an extensive range of customer defined options and accessories delivers the ultimate platform for your application needs.

• Integrated Mazak Technology delivers class leading accuracy and repeatability. • Reduced load and unload time for maximum spindle utilisation. • Flexibility to meet changing application needs. • Enhanced productivity through easy to program Mazatrol CNC. • Superior Operator Ergonomics